What is Indium Tin Oxide (ITO) glass?

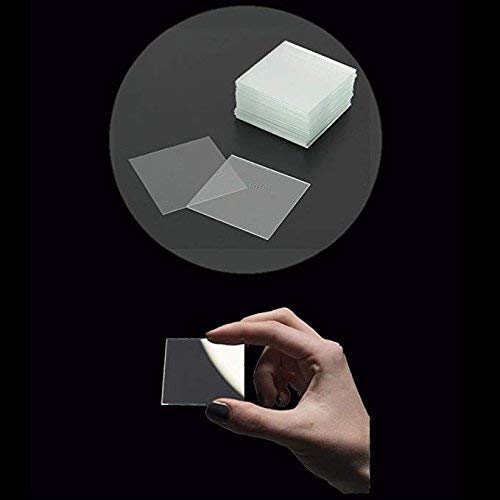

The ITO conductive glass is formed by coating a layer of indium tin oxide (commonly known as ITO) film by sputtering, evaporation, or the like on the basis of a soda-lime-based or silicon-boron-based glass. Most electronic displays currently use ITO glass as their screen.

The ITO conductive glass applied to the liquid crystal display also needs to be coated with a silicon dioxide barrier layer before the ITO layer is plated to prevent sodium ions on the substrate glass from diffusing into the liquid crystal in the cell. The ITO glass substrate for liquid crystal display is generally ultra-float glass, and all the coated surfaces are glass float tin surfaces. Therefore, the final liquid crystal display will follow the direction of the float, and irregular ripples will occur regularly.

The main component of the ITO film layer is indium tin oxide. When the thickness is only a few thousand angstroms, the indium oxide has a high transmittance and a strong electrical conductivity. The ITO glass used in the liquid crystal display is such a conductive glass having a high transmittance. However, since ITO has a strong water absorption property, it absorbs moisture and carbon dioxide in the air and chemically reacts and deteriorates. It is commonly called "mildew", so it should be protected from moisture during storage.

The ITO layer is composed of many fine crystal grains, and the crystal grains are fissioned and become smaller during the heating process, thereby increasing more grain boundaries. When electrons break through the grain boundary, a certain amount of energy is lost, so when the temperature is below 600 degrees, the resistance of the ITO layer of the ITO conductive glass increases as the temperature increases. The characteristics of the ITO layer are related to the target type, temperature and mode of motion. It is possible to selectively change the characteristics of the ITO layer to obtain the desired ITO layer from these aspects.

Stanford Advanced Materials (SAM) Corporation is a global supplier of various evaporation materials such as metals, alloys, oxides and ceramic materials, which are widely used in multiple industries. We regularly update knowledge and interesting stories of sputtering targets on our website. If you are interested, please visit https://www.sputtertargets.net/ for more information.